Smart Sensor

Intra Oral X-Ray Image sensor

- High Quality X-ray Image Sensor

- Structured Scintillators (SCINT-X*) Mounting

- Sensor Angle Information

Benefit

- Increase Image Quality

- Reduce Liability

- Easy to Align with Smart Locator

- Correct Parallel Align with Smart Locator

- Comfort Patient Care

The structured scintillator technology

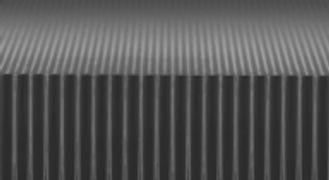

Conventional scintillators lack precision

Unfortunately, there is a major issue with conventional scintillators. The created light spreads while it travels through the scintillator, which results in a light cone rather than a light spot. Thus, the image sensor would register a signal on several pixels for each incident x-ray. The amount of absorbed x-rays and therefore signal strength depends on the material thickness. Therefore, conventional scintillators involve a trade-off between sensitivity and resolution.

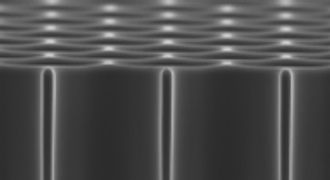

Silicon channels the light

The structured scintillator technology overcomes the drawbacks of conventional digital x-ray detectors. While the visible light created through x-ray absorption spreads on its way through the crystal in unstructured scintillators, the innovative concept developed and patented by Scint-X* channels the light on its way to the sensor. Narrow pores are etched into silicon in order to manufacture a matrix that can be filled with a scintillator material like Thallium doped Cesium Iodide.

Sensitivity and resolution

Thus, the spreading of created light, that would lead to crosstalk between neighboring pixels on the sensor, can be avoided. This means that the structured scintillator can be optimized with respect to sensitivity without loss of resolution.

*http://www.scint-x.com

The structured scintillator

Smart Locator

How the Smart Locator works

Cone Cut Images

Less exposure when collimator is located closer to sensor

Result = Retake = More Exposure = More time and Unhappy Patient, Mad Dentist, Frustrated Staff

Less exposure when collimator is located closer to sensor

Less exposure when collimator is located closer to sensor

User suggests Engineers to invent for them

User suggests Engineers to invent for them

- Intuitive Software

- Comfortable Design

- Time and Cost Saving Features

- Highest resolution

Benefit

- Better Quality Image

- Reduce the chance of Cone-cut

- No retake: Time saving and less rediation

- Easy staff education and transition

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.